🎨 Blasting & Painting Services — Precision Meets Protection

At GML, surface preparation and coating is not just a task — it’s a science. With state-of-the-art facilities, certified professionals, and over a decade of trusted industry performance, we deliver consistent quality on every project — onshore or offshore.

🧱 Facility Overview

Our main blasting and painting facility is built for efficiency, safety, and scale:

🏢 2,000 sq. ft. fully enclosed blasting room

Sweep-in abrasive recovery system

Capable of blasting equipment up to 40ft container size

🎨 1,000 sq. ft. enclosed painting room

Dust-free, climate-controlled for high-quality finishes

♻️ Garnet abrasive recycling system to reduce environmental impact

🌍 Committed to Sustainability & Clean Technology

💨 All operations done in sealed, filtered environments to reduce contamination

♻️ Garnet abrasive is recycled in-house to minimize waste

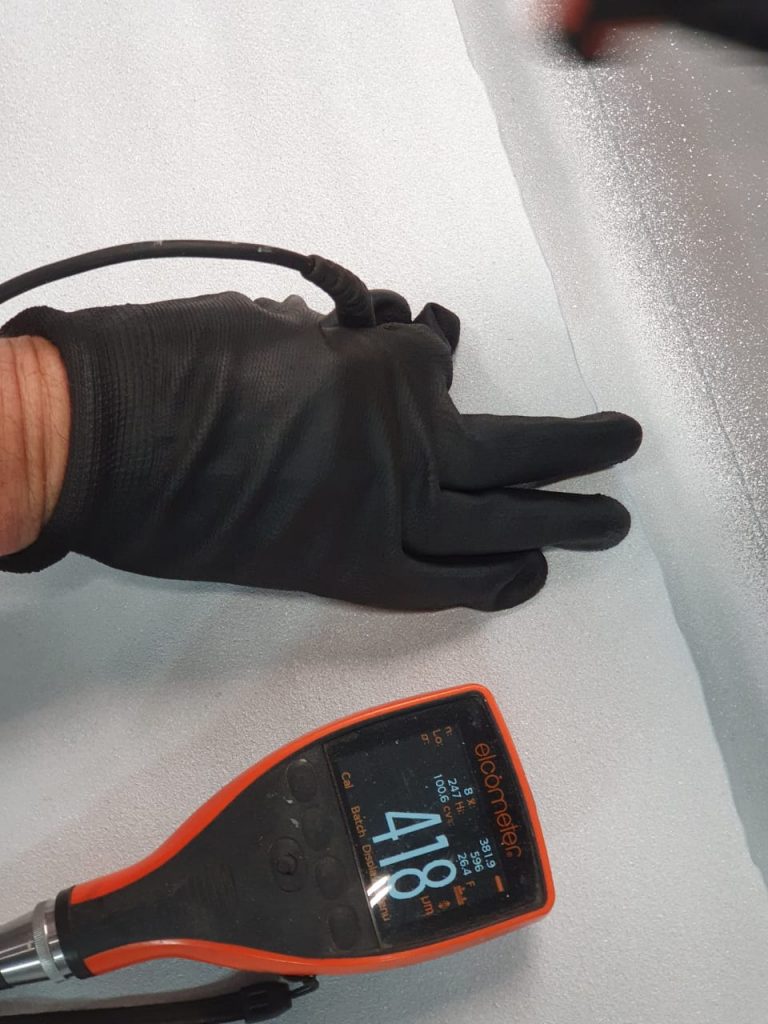

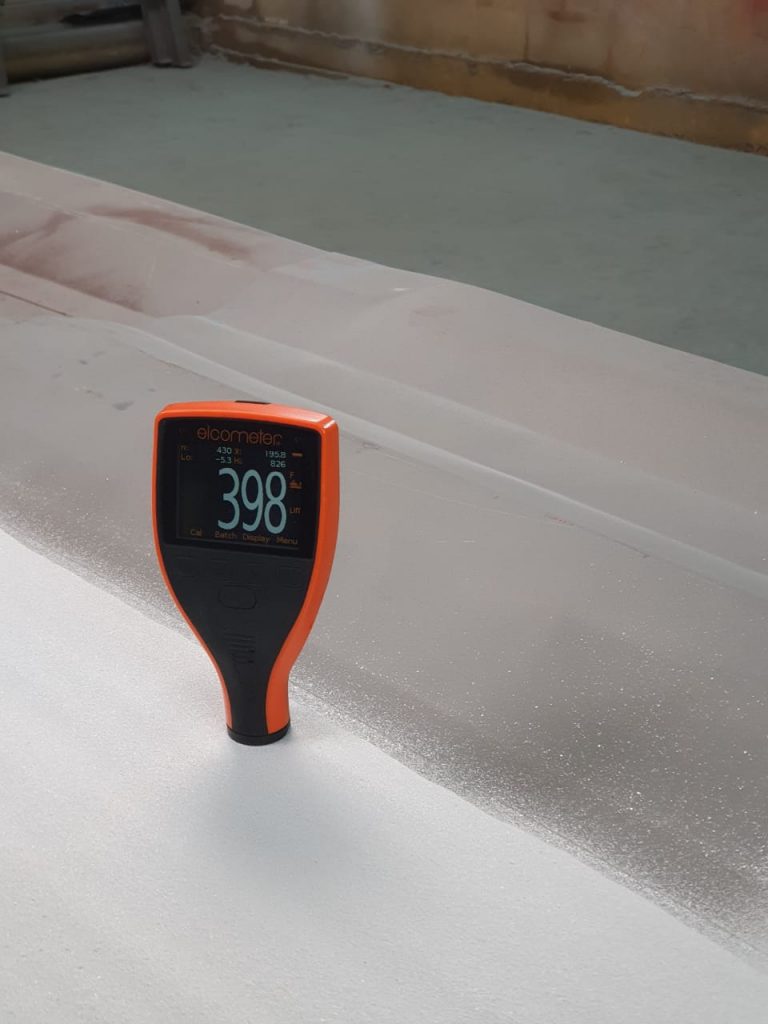

🌐 Among the first in the region to implement a fully digital Elcometer inspection system for coatings

🛠️ Certified Expertise That Sets Us Apart

Our work is backed by globally recognized standards and certified professionals:

🧪 AMPP Certified Inspectors (formerly NACE) on site for every job

🎓 SSPC Train-the-Painter certified blasters and applicators

📋 Inspections documented with coating thickness reports, surface prep verifications, and full QA/QC documentation

🌊 Offshore-Ready. Industry Trusted.

⛴️ Over 10 years of experience blasting and painting offshore valves and components

🔒 Trusted by leading energy and industrial companies for fast turnaround and consistent quality

⚙️ We maintain a reputation for meeting tight deadlines without compromising quality

🏅 Why Choose GML for Blasting & Painting?

Purpose-built, enclosed facilities for dust-free, controlled operations

Certified staff with international credentials

Fully digital inspection & documentation process

Environmentally conscious blasting practices

Proven offshore capabilities with a decade-long track record