⚡ Metallizing Services — Advanced Corrosion Protection, Anywhere

GML is one of the few companies in Trinidad & Tobago offering full-service thermal spray metallizing. We have the equipment, experience, and facilities to apply long-lasting, corrosion-resistant metallic coatings to virtually any surface — in-shop or in the field.

🔩 What is Metallizing?

Metallizing (thermal spray coating) is the process of applying molten metal to a surface to create a durable, corrosion-resistant layer — similar to hot-dip galvanizing but more versatile and cost-effective.

⚙️ Why Choose Metallizing Over Galvanizing?

🔥 No weight-based pricing — more cost-effective than hot-dip galvanizing

🌡️ Ideal for areas where hot dipping is impractical or impossible

📍 Can be performed on-site or in the field

💪 Offers equivalent corrosion resistance to hot-dipped zinc coatings

🧪 Capabilities & Equipment

✅ Full thermal spray metallizing system in-house

🧲 Coatings can be applied to steel, aluminum, copper, and more

🧼 Metallizing is performed immediately after abrasive blasting, ensuring maximum adhesion and finish quality

🏢 Process done within our fully enclosed blast and spray facility

🔧 Custom Wire Coating Options

We can supply and spray a variety of wire metals to suit your project:

🧪 85% Zinc / 15% Aluminum alloy

🧪 99% Pure Aluminum

🧪 Copper, Zinc, and other custom alloys on request

🌍 On-Site or In-Shop Application

🏭 In-house metallizing for small and large parts in our controlled environment

🚛 Field-capable thermal spray units for on-site coating where mobility is essential

🔒 Ensures consistent finish and maximum protection even in remote or complex settings

🏅 Why GML for Metallizing?

One of the few certified providers in the region

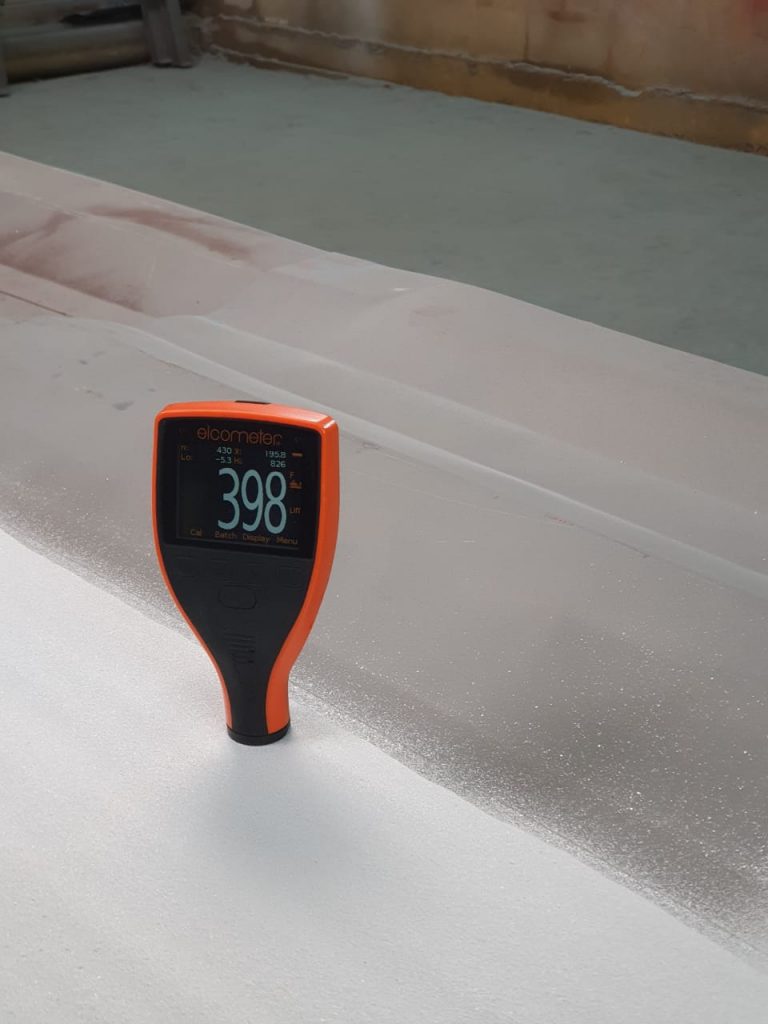

Highly trained operators and strict quality control

Integrated blasting + metallizing facility means faster turnaround

Proven results in corrosion resistance and cost efficiency